Research Article - (2023) Volume 12, Issue 1

There is no bigger industry on our planet than food and agriculture. In fact, the World Bank estimates that food and agriculture comprise about 10% of the global GDP (Gross Domestic Product). Despite a huge customer base, the food industry is facing unprecedented challenges in production, demand and regulations stemming from consumer trends. Due to the involvement of humans, the food industries are failing to maintain the demand-supply chain and lacking in food safety. To overcome these issues in food industries, industrial automation is the best possible solution. Automation is completely based on Artificial Intelligence (AI) or Machine Learning (ML) or Deep Learning (DL) algorithms. Artificial intelligence with data science can improve the quality of restaurants, cafes, online delivery food chains, hotels, and food outlets by increasing production by utilizing different algorithms for sales prediction. Artificial Intelligence (AI), a radical concept developed by computer scientists in the 1950s, has tremendous applications in our daily lives. Artificial intelligence aims to learn human cognitive abilities and eventually surpass them. Currently, most AI models rely on deep neural networks, inspired by the human brain, which takes in a lot of raw data and expects results and learns the relationship between the two.

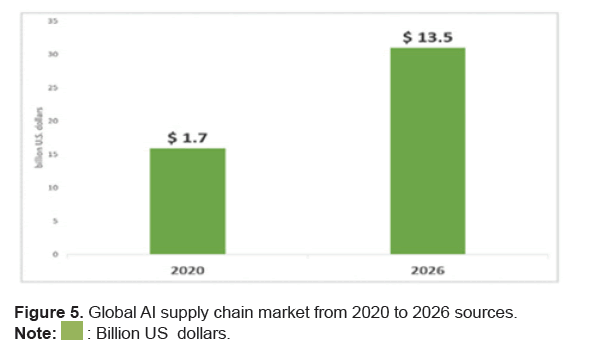

The Global AI in the Supply chain market reached USD 5,610.8 Million in 2021a across the globe. Increasing attention to artificial intelligence, large statistics, analytics, and a widening scope are all driving AI growth in the supply chain market globally. According to Taradata, 2022 every autonomous and semi-autonomous program implements computer vision. There are several players operating in the global AI supply chain market, including FedEx, McLane Company, DHL, Amazon, CSX, XPO Logistics, C.H, and others. The machine learning segment accounted for the largest share of the global AI in the supply chain market.

I tried to find these answers through my research article.

• Importance of AI and how will impact in Supply chain in the mid- and long-term?

• What are the ubiquitous movements in AI in the Supply chain?

• What are the key strategies adopted by leading companies For AI in Supply chain logistics?

• How can the implementation of AI make the Supply chain more efficient?

To answer all these questions, I use Primary as well as secondary data and reports from conducting surveys and various government agencies. I did SWOT analyses to check where we can implement AI in supply chain optimization. With the help of BCG matrix, I tried to give suggestions to Industry how revenue can be increased with the correct implementation of AI.

Food industry • Supply chain • Artificial intelligence • SWOT analysis • BCG matrix

AI (Artificial Intelligence)

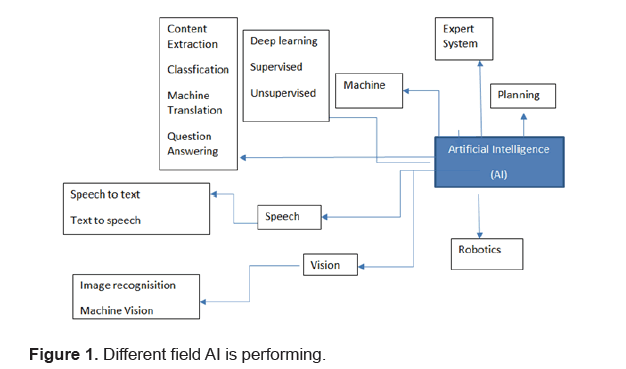

In my words AI is now a days appear as allover in every nook and cranny. Computer scientists invented the AI and now AI is paying back. The aim of AI to create intelligent machines that enables machines to think like a normal human [1]. Wherein cognitive functions of the human’s brain are studied and AI tried to be replicated on a machine / system. AI is today widely used for various functions like computer vision, speech recognition decision making, perception, reasoning, cognitive capabilities, and so on in the figure, we can get an idea about all the different fields AI is performing (Figure 1).

Figure 1: Different field AI is performing.

My article used survey research as well as secondary data gathered from various known sources. Using descriptive statistics, I analyzed the data. I also did SWOT analysis and BCG matrix analysis to take better decisions.

Domain of artificial intelligence

In the figure, we can get an idea about all the different fields AI is performing (Figure 1).

Now the next thing to be considered here is how we can use AI intelligently to make efficient supply chain. So, let us know a little bit about the supply chain then we will connect this t o AI [2].

About supply chain

A supply chain is a grid between a firm/business and its suppliers to produce and distribute a specific product to the final buyer/consumer. Networks consist of different activities, people, entities, information, and resources. The supply chain also represents the steps it takes to get the product or service from its original form to the end user. Companies developed the supply chain to reduce costs and remain competitive in market. Supply chain management optimized supply chain for faster production cycle in low cost. (Supply Chain Intelligence, 2021)

Supply chain management is essential to any business to be successful.

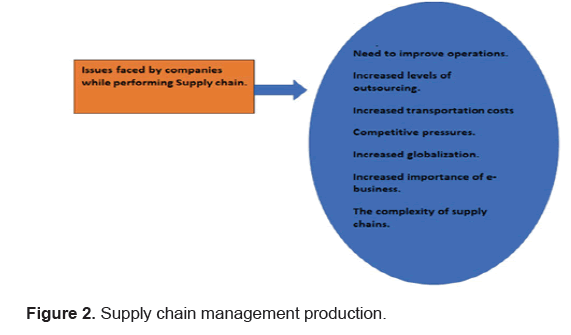

There are lots of issues faced by companies while performing supply chain; some of them include [3].

Supply chain management is the process, and it has so many elements involve in it, let us try to understand with this table. On the left column of the table explains elements at each level and supply chain and the right column explains the corresponding activities of each element (Figure 2).

Figure 2: Supply chain management production.

Supply chain mechanization

As it is known, supply chain is a network that connects all the business apparatuses such as manufacturing, procurement, planning, sales, and marketing together. The ongoing impact of pandemic effects demonstrated how the Supply chainrings down the companies. Many organizations, therefore, add digital solutions frequently to optimize the operations of the supply chain. The foremost pronouncement zones in supply chain management are location, production, distribution, and inventory. Managers are taking either strategic or operational decision accordingly. The location decision relates to the choice of locations for both production and distribution facilities. Where production and transportation costs and delivery periods are vital. Production and distribution decisions focus on what, when and how much customers need. Subcontracting can be contemplation.

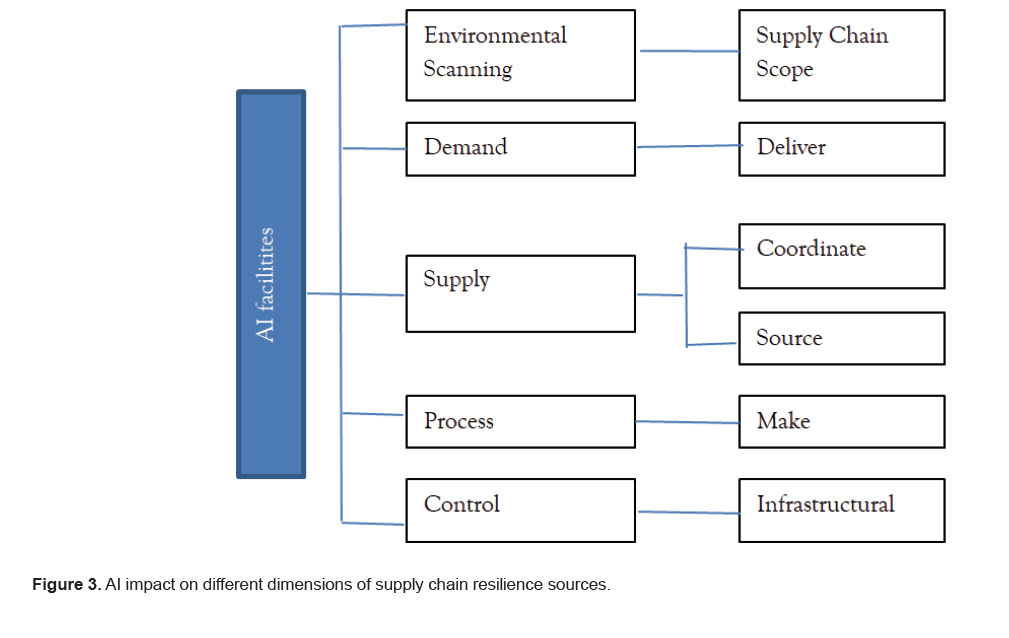

Because transportation costs are often a huge portion of total costs, distribution decisions are strongly influenced by transportation costs and delivery times. The operational decisions are based on schedule, maintaining equipment, and meeting customer demands. It is also important to consider quality control and workload balancing. It involves determining inventory needs and coordinating production and stocking decisions across the supply chain. In inventory decision, logistic management plays a crucial role Logistic management plays a crucial role in inventory decision (Figure 3).

Figure 3: AI impact on different dimensions of supply chain resilience sources.

AI based supply chain

• The use of artificial intelligence in supply chains can increase efficiencies and improve customer service. Any company's strategy must include these goals, as they help the company save money and keep customers satisfied.

• In an agricultural production set, AI is helping by collecting substantial amounts of data which can be extremely hard to analyze as a human being, and according to those data decision-making is easier now. Oracle and automation can help companies shift from completing repetitive and tedious tasks to considering the bigger picture, which saves both time, money, and human error [4-8].

• In response to a continual inflow of new customer orders, AI is helping by predicting when inventory shortages will occur.

• AI facilitates Environmental Scanning Supply Chain Scope (macro) Demand.

Data collection and data analysis

I conducted in-depth interviews and contacted 250 supply chain and AI professionals via email and LinkedIn messages in June 2022 and provided a brief introduction to the research topic. After multiple reminders, 67 respondents replied and showed interest in sharing their views on the topic. However, of these, only 46 respondents finally agreed to be interviewed. Interviews were conducted in July, telephonically and over Internet-based calls to get the response fast. To maintain confidentiality, we have anonymized the respondents (A1–A35, A stands for Attendee, 1-46 are Interviewees numbers) and provide full details in table: Details of interviewees (Table 1) [7].

| Interviewee profile no | Interviewee code | Job title | Years of experience | Survey | Yes |

|---|---|---|---|---|---|

| 1 | A1 | Supply chain analyst | 7 | Yes | 1 |

| 2 | A2 | Managers | <8 | no | 0 |

| 3 | A3 | Supply chain operation | 10 | Yes | 1 |

| 4 | A4 | Business analyst | 10 | Yes | 1 |

| 5 | A5 | Senior Manager | 12 | Yes | 1 |

| 6 | A6 | Inventory Engineer | <9 | Yes | 1 |

| 7 | A7 | Plant Manager | <6 | no | 0 |

| 8 | A8 | Distribution Manger | 6-7 | Yes | 1 |

| 9 | A9 | Executive consultant | 8 | no | 0 |

| 10 | A10 | Supply operation Manager | 9+ | Yes | 1 |

| 11 | A11 | Executive Manager | 14 | no | 0 |

| 12 | A12 | Associate Manager | 12+ | no | 0 |

| 13 | A13 | Manager | <10 | Yes | 1 |

| 14 | A14 | Supply chain Analyst | 6 | Yes | 1 |

| 15 | A15 | Business operation Manager | 7 | Yes | 1 |

| 16 | A16 | Inventory Manager | 5 | Yes | 1 |

| 17 | A17 | Vice president sales | 8 | no | 0 |

| 18 | A18 | Engineer | 5 | Yes | 1 |

| 19 | A19 | Inventory Manager | <9 | Yes | 1 |

| 20 | A20 | Inventory Manager | 7+ | Yes | 1 |

| 21 | A21 | Supply chain analyst | 6 | Yes | 1 |

| 22 | A22 | Managers | 9 | Yes | 1 |

| 23 | A23 | Executive consultant | 12 | no | 0 |

| 24 | A24 | Supply planner | 15 | Yes | 1 |

| 25 | A25 | Managers | 19 | Yes | 1 |

| 26 | A26 | Director | 17 | Yes | 1 |

| 27 | A27 | Business operation Manager | 6 | Yes | 1 |

| 28 | A28 | Consultant | 8 | no | 0 |

| 29 | A29 | Supply chain analyst | <9 | Yes | 1 |

| 30 | A30 | Managers | 6-7 | Yes | 1 |

| 31 | A31 | Associate consultant | <8 | no | 0 |

| 32 | A32 | Supply operation Manager | 6+ | Yes | 1 |

| 33 | A33 | Director | 12 | Yes | 1 |

| 34 | A34 | Executive consultant | 14 | no | 0 |

| 35 | A35 | Business operation Manager | 10 | Yes | 1 |

| 36 | A36 | General Manager | <8 | Yes | 1 |

| 37 | A37 | Inventory Manager | <5 | Yes | 1 |

| 38 | A38 A39 | Supply planner | 7+ | Yes | 1 |

| 39 | A40 | Associate consultant | 4-5 | Yes | 1 |

| 40 | A41 | Supply chain operation Manager | 6 | Yes | 1 |

| 41 | A42 | Director | <6 | Yes | 1 |

| 42 | A43 | Managers | 9 | Yes | 1 |

| 43 | A44 | Executive consultant | 10 | Yes | 1 |

| 44 | A45 | Business Analyst | 12 | Yes | 1 |

| 45 | A46 | Supply operation Manager | 10 | Yes | 1 |

Table 1: Use-case of AI in food and Supply chain mechanism.

Graphical presentation

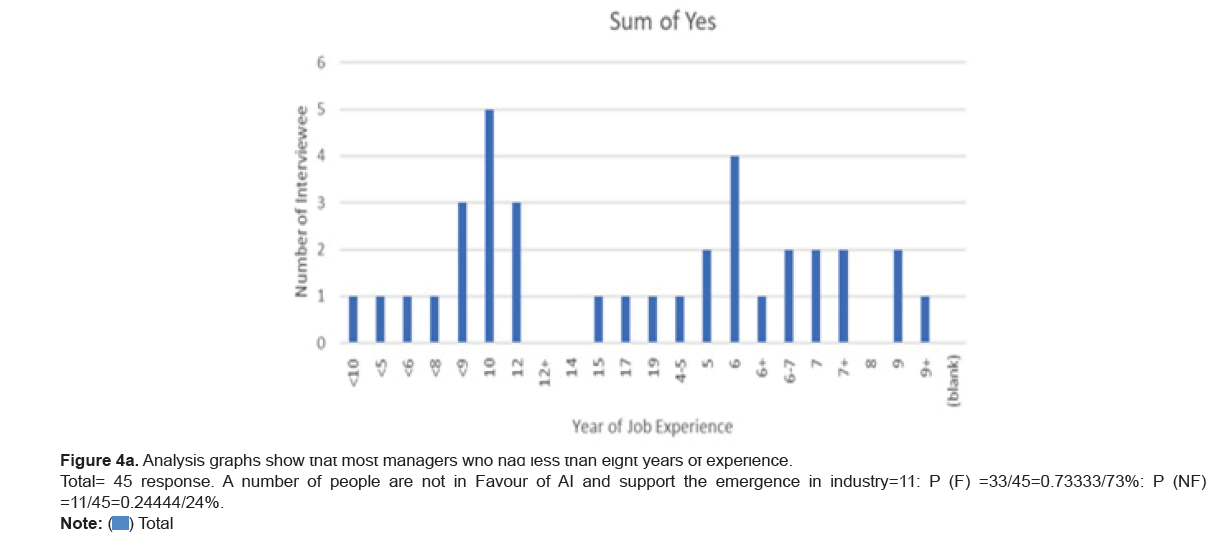

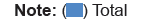

With the data analysis of the survey, I found that the grand total of respondents in favor is 20 and in which executive consultants has noticeably higher respondents in Favour of AI (Figures 4a-4c).

Figure 4a: Analysis graphs show that most managers who had less than eight years of experience. Total= 45 response. A number of people are not in Favour of AI and support the emergence in industry=11: P (F) =33/45=0.73333/73%: P (NF) =11/45=0.24444/24%.

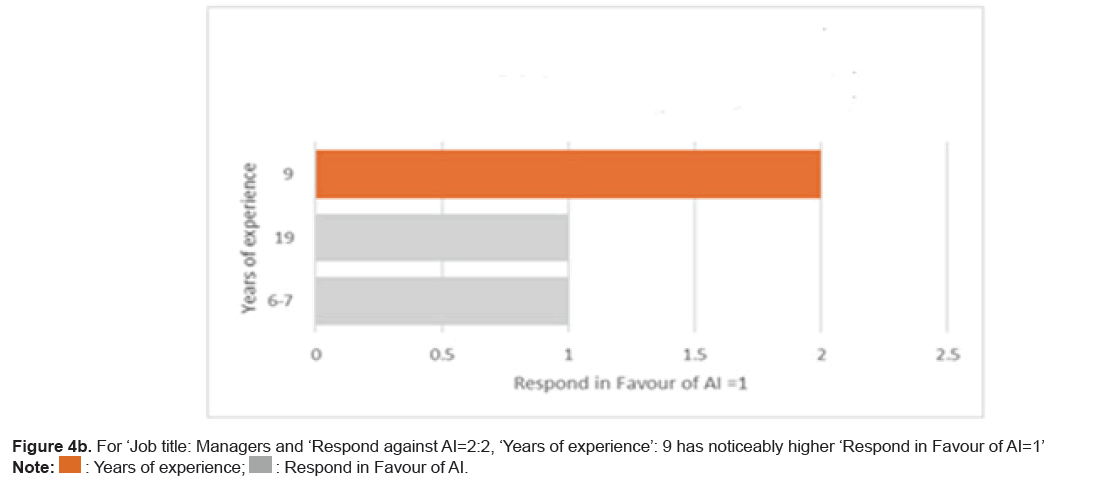

Figure 4b: For ‘Job title: Managers and ‘Respond against AI=2:2, ‘Years of experience’: 9 has noticeably higher ‘Respond in Favour of AI=1’

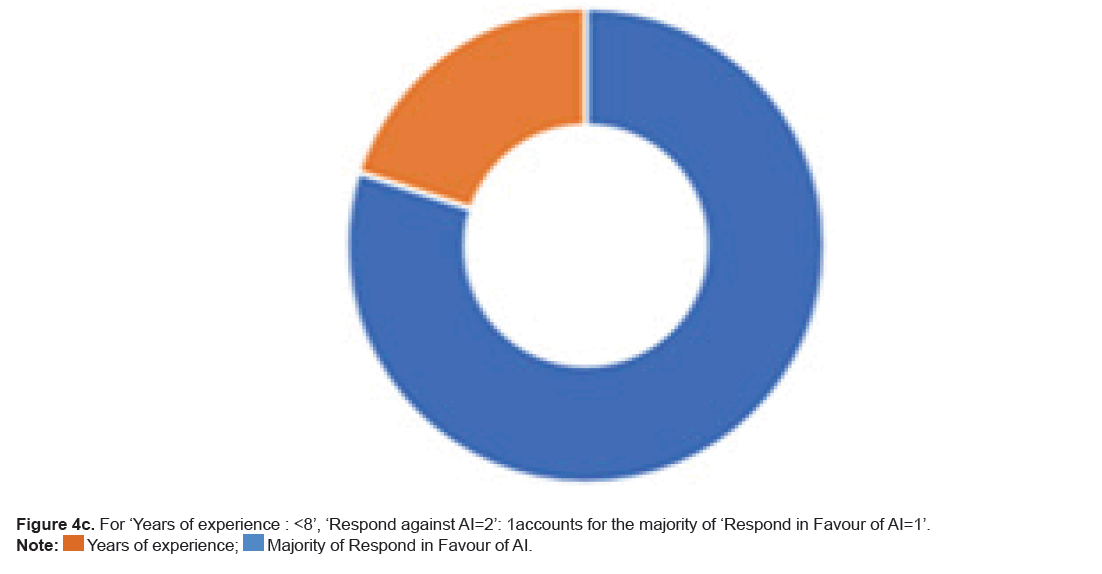

Figure 4c: For ‘Years of experience : <8’, ‘Respond against AI=2’: 1accounts for the majority of ‘Respond in Favour of AI=1’.

Here the analysis graphs show that most managers who had less than eight years of experience responded more in favor of AI emergence in the SCM area for their company.

Total=45 response

A number of people are not in Favor of AI and support the emergence in industry=11

Number of people in Favor of AI and support implementation in industry=33

P (F) =33/45=0.73333/73%

P (NF) =11/45=0.24444/24%

Some factors that can be considered in supply risk and after interviewing these 45 people I came to the below are the point to be considered for use of AI in this area.

• Often, suppliers struggle to find staff to run their facilities and training new employees slows down production as well. Here AI helps and plays a key role, companies are using AI for time being or replacing the labor requirement, usually for repetitive kind of work and which can perform by AI in better way.

• Preventative Maintenance (PM) planned to limit unscheduled down time. PM is known to decrease the number of unplanned machine breakdowns, which helps plants, stick to the production schedules.

• Using artificial intelligence, we can monitor production delays, request additional parts because of quality issues or higher demand than forecasted, and decide on new and existing suppliers based on the best, most informed information.

• In many companies, filling in informational gaps after employees’ leave is a major challenge.

• When one of the members of the company leaves, the rest will find it extremely difficult to cope. At this point in time companies are using AI to fill in the gaps.

• In many companies, language barriers are a major issue. Many of these language barriers can be eliminated using artificial intelligence.

• It is important to manage supplier-customer relationships and ensure on-time delivery by working with customers. Companies are using chatbots, or automated communication systems that answer questions and provide customer service. AI also helps to reduce “... the amount of time everyone spends trying to make sure customer orders get shipped on time” (Green, “Artificial Intelligence for Real-Time Manufacturing Execution and Operations Management”).

• In the production process, AI is helping to identify a depraved portion of produce by spotting these bad parts through cameras.

• In many cases, future sales can be predicted using data mining and predictive analysis, both of which can be assisted by artificial intelligence. Using artificial intelligence, companies can manage this data more efficiently, produce better products, and be more productive [9].

Global AI supply chain market from 2020 to 2026

Artificial Intelligence is a popular technology that is making every sector smarter and more resilient. The global supply chain AI market is projected to reach $13.5 billion (about $42 per person in the US) (about $42 per person in the US) (about $42 per person in the US) by 2026. (IDC: Accelerate Innovation and Sustainable Competitive Advantage with a Solid Data Strategy for AI Technology, 2021) AI improves supply chain planning by helping food and beverage companies to forecast demand against product supply and ingredient orders. The AI platform can take inputs from supply chain management professionals to develop algorithms that inform procurement decisions. Delivery of ingredients to the appropriate manufacturing facilities can also be optimized, as AI allows for highly specific predictions around when and where resources are needed (Figure 5).

Figure 5: Global AI supply chain market from 2020 to 2026 sources.

Warehouse and inventory management in food supply chain

AI algorithms can also help forecast demand on warehouse resources and analyze inventory against shipments going out and new products coming in.

Automated procurement

In a far-off (or not so far-off) future, we could see the size of procurement teams shrink as the use of automation grows. Procurement teams may be focused more on finding the right vendors and establishing vendor connections than on decisions to get what is needed from short supply chains [10-13].

Quality assurance and protecting global food supply

Cornell University and IBM are partnering up to utilize AI to learn how to better protect the global food supply so that when some amount of product is contaminated, thousands or millions of pounds do not have to needlessly go to waste.

Food and beverage manufacturers are utilizing AI through better predictions of what food has been contaminated, to make sure that these products do not reach consumers.

Remove language barriers that threaten auditing and compliance

Language barriers can be a huge problem when communicating with suppliers over product specs, agreements, certifications, and other nitty-gritty details. This later creates a potential risk for auditing and compliance issues. In your view, the supplier agreed to something that they did not agree to. Or you interpreted their explanation in a separate way?

AI technology for supply chain management and procurement can alleviate the risk of foreign communication by reading foreign language data on your behalf and translating it into data that can be understood and utilized [14].

Driverless vehicles and other logistics optimizations

Tesla is working on a driverless semi-truck that has the potential to revolution warehousing, logistics, distribution, and transportation in every physical product industry not just food and beverage.

Consumer visibility

One of the key use cases for AI in the food and beverage industry is offering better visibility into what consumers need and how frequently. Currently, data silos between marketing and product creation can negatively impact sales [15-18].

Better consumer visibility should be able to come from a variety of various sources: federal or demand forecasts for certain products and trends, private demand forecasts that manufacturers and brands can purchase, sales data from retailers, demand statistics from real product orders, and more.

Without AI, it would be impossible for humans to integrate, clean, and utilize all these disparate data sources.

Difficulties to implement AI in food supply chain

As we all know an area influences machine learning and artificial intelligence to help enterprise retailer and organizations make better decisions across their supply chain.

AI being utilized in a couple diverse ways from kind of pre-season demand planning through to merchandising and buying decisions through planning and allocation and decision in the terms of in inventory availability and assortment. AI being utilized to decide what to make available across the supply chain throughout like where to fulfill the inventory from across distribution centers and now also to stores, also through the rout optimization and last mile. So, it is across industries. It is outside of retail also, but retailer and brands are main utilizers, they are pure AI-player’s e-commerce and some PG also in the list of users of AI [19].

If we analyzed applicability of AI in current scenario, there is lots of opportunities to leverage machine learning and AI with obviously some challenges to implement it outside of the lab and bringing it market and commercialization it and productizing it. Although there all lots of challenges but the biggest one the data itself as if one think about AI, it is really for identifying patterns making better decisions and predicting, making predictions about business outcomes based on data, so it difficult to collect data and curate, to cleans, to get in to format to use for business. AI needs technologies and skill to engineer the data to build that pipeline to bring that data to organization and adjust in the way as it’s needed so that analytics runs it and make better decisions.

Black box there is lots of concerns about black box and artificial intelligence when AI start to enter in the business, there was lots of concerns about how can machines take a decision for human?

So, to clarify that for solving very discrete problems and isolating the problem space organization have more visibility into how decision is being made, transparency about the computation and the decision-making process the software is working that the model is running and that the transect in all the organization and all the units is essential. Visibility of metrics is important to looking at the actual business impact and sharing its cross functionality is critical [20-23].

The benefits that the company is going to receive after AI investment is to solve very discrete problem so that you quantify the current stage to so company can understand how decision can be today which track those decisions and documents. Another thing is comparing, the ways that AI model is running the machine and is making those decisions. So, comparison is important and having a closed loop in terms of what was the decision-making process before and what is today [24-26].

In supply chain, this type of technology operative in every chain of process in next five year if we see the picture for the supply chain as different retailers and manufacturer and even CPG (Consumer Packaged Goods) as they make decisions in terms of where to make investments in their supply chain, they are going to see impact on customer service, customer promise state. AI will make competent to compete in the market, and to know better the customer requirement for further decision [27-32].

Digital platforms help in tracking the discarded packaging material and products. It also helps customers to get salvage value for the discarded product and feel motivated to cause and loyal to the company [33].

SWOT analysis

To overcome these issues in food industries, industrial automation is the best possible solution. Automation is entirely based on Artificial Intelligence (AI) or Machine Learning (ML) or Deep Learning (DL) algorithms. Artificial intelligence with data science can improve the quality of restaurants, cafes, online delivery food chains, hotels, and food outlets by increasing production n by utilizing different fitting algorithms for sales prediction. Artificial Intelligence (AI), a radical concept developed by computer scientists in the 1950s, has tremendous applications in our daily lives. Artificial intelligence aims to learn human cognitive abilities and eventually surpass it. Currently, most AI models rely on deep neural networks, inspired by the human brain, which takes in a lot of raw data and expects results and learns the relationship between the two. (IBM Cloud Education, 2020) The relationship between AI and humans makes the supply chain a more efficient industry [34-36]. The industry can SWOT analysis to define the best use case of AI in every part of the supply chain to get the maximum out of it (Tables 2 and 3).

| Strength | Weakness |

| How can AI strengthen the original sourcing or extraction of raw materials during the food/ Agriculture production process? How we can Use AI to refine ingredients in the basic preparation of food? How can AI make it easy and timesaving to collect basic chunks into finished products? How can AI help in Selling finished products to end users? AI can be best used in Delivering finished products to end users or consumers. | What could be improving in supply chain operations of food industry with the help of AI? Which Supply chain operation is lack of application of AI for better result? What are the market competitors mentioned if there is any lacking or weaknesses operations? |

| Opportunity | Threats |

| This section makes you understand that what could be the opportunity if we implement AI in all supply chain operation? To understand the trend and how you can implement it? How food industry can be more efficient in supply chain optimization with the AI? | Here industry can analyse what are the things which are going to be adverse effect on SCO? What are the competitors using strategy? What threats your weakness expose to you in market? |

Table 2: Use-case of AI in food and beverages supply Chain SWOT Analysis.

| ELEMENT | TYPICAL ISSUES |

|---|---|

| Customers | Determining what products and / or services customers want. |

| Forecasting | Predicting the quantity and timing of customer demand |

| Design | In corporating customers, wants, manufacturability, and time to market |

| Capacity planning | Matching supply and demand |

| Processing | Controlling quality, Scheduling work. |

| Inventory | Meeting demand requirements while managing the costs of holding inventory |

| Purchasing | Purchasing evaluating potential suppliers supporting the needs of operations purchased goods and services |

| Suppliers | Monitoring supplier quality, on time delivery, and flexibility; maintain supplier relations |

| Location | Determining the Location of facilities |

| Logistics | Deciding how to best move information and materials |

Table 3: Supply chain mechanization process.

AI-lead supply chain optimization software strengthens important decisions by using cognitive predictions and commendations on optimum actions. Supply chain managers gain cavernous insight and regulate every aspect of the chain with AI's ability to predict future demand, automate processes, and increase transportation efficiency. As far as the AI's present trend is concerned, it will encourage creativity, free human beings from mindless or complex tasks, and even replace humans in dangerous occupations. Combined with digitization and intelligent upgrading of the industry, AI technology will drive a future of unlimited possibilities. Gartner estimates that 80% of new supply chain applications will involve artificial intelligence and data science by 2025 (ANALYST REPORT, 2022).

Citation: Pandey S. ''AI-Lead Supply Chain Optimization in Food Industry.''J Biol Todays World, 2023,12(1), 001-007.

Received: 10-Nov-2022, Manuscript No. jbtw-22-79926; Editor assigned: 14-Nov-2022, Pre QC No. jbtw-22-79926(PQ); Reviewed: 30-Nov-2022, QC No. jbtw-22-79926; Revised: 10-Dec-2022, Manuscript No. jbtw-22-79926(R); Published: 30-Jan-2023, DOI: 10.35248/2322-3308.12.1.001

Copyright: © 2023 Pandey S. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.